Considering the Moisture Content before Building Fuel Brique

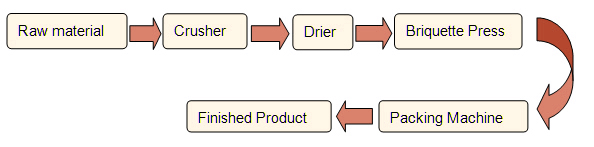

An important question that you need to consider when you are building an efficient fuel briquettes plant is that of moisture content. Briquetting will be possible only where the moisture content of the raw materials is within the recommended level. Using the example of a plant which needs to produce 2800-3600kg per hour, the moisture content of your raw materials should not exceed 6-16%. If it goes beyond this range, you must make sure that the particles are dried properly lest they all get damaged and you end up incurring a lot of losses.

Final Products of Fuel Briquettes Plant

Wood chips, sawdust, sunflower seed husk, sugar cane bagasse, rice husk, peanut shell, tree trimmings, wood logs, etc. The size of raw material should be less than 5*5mm and the moisture content should be around 8%. All the materials above can be made into various shapes according to different fuel briquettes requirements by using different rollers.

Contact us if you are interested in knowing more about fuel briquetting process or want more details of AGICO fuel briquettes Plant.

800~1000kg/h Sawdust Briquetting Assembly Line

800~1000kg/h Sawdust Briquetting Assembly Line

1Ton/Hour Wood Briquette Plant

1Ton/Hour Wood Briquette Plant

10 Ton Coal/Mineral Powder Briquetting Plant

10 Ton Coal/Mineral Powder Briquetting Plant