How Wood Briquettes are Made?

Agro Briquette Plant Project by Briquetting Plant Manufacturer developing a technology by which forestry and industrial waste converted into solid fuel called Biomass Briquettes. Today more than ever, it makes good business sense to recover energy from production residues. an effective solution to the question of how to turn dusty waste materials created during the production process into Briquettes Press which can then be fed back into the energy cycle.Briquetting Plant has developed interest because of ecological and expense element. Utilizing briquetting plant is the preferred arrangement over pellets. Creating wood pellets is exceptionally costly and the vitality utilized as a part of the procedure lessens the estimation of the pellet as fuel. The thickness of pellets is roughly the thickness of the wood utilized as a part of assembling it.

Biomass briquetting procedure is a generally straightforward strategy for turning wood waste, green waste, saw dust into bio fuel. Two parameters expected to tell:

- The crude material supplied to briquetting machine needs to have molecule size.

- The dampness substance should be between eight to ten.

The aggregate vitality utilized by briquetting procedure is not exactly the vitality used to make pellets. The machine used to make pellets is exceptionally costly and require steady and financially savvy upkeep. The thickness of completed biomass briquettes is about twice than the thickness of the wood utilized as a part of assembling it. These briquettes can be utilized as a part of boilers and also stoves.

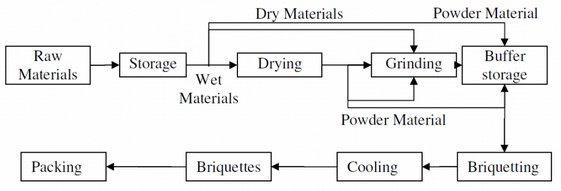

Briquetting plant have high capacity to change over crude material into fuel briquettes. These materials including green waste, wood waste, reuse paper and cardboard, strands etc.€¦ Briquetting machines pack the crude material without utilizing any coupling at inexact 300 degrees in temperature. Biomass briquetting is most advantageous and effective system, in the meantime create most stable biomass briquette. Contingent upon the nature of crude material and your significance, you may need to include some additional machines for crushing, drying and taking care of the crude material. There are cutter/Crusher, Dryer and mallet factory accessible in the mechanical business sector for pounding and drying crude material.

How biomass briquettes are useful to keep up environment green?

Biomass Briquette Press for Sale

To control the earth contamination, utilization of briquettes is a key reason as the briquettes are produced using farming waste, wood waste, and mechanical waste with the assistance of biomass Briquetting machines. There are various Briquetting machine producers the individuals who fabricate unrivaled quality Briquetting machines and convey high volume briquette.

In the event that the wood is as of now excessively dry, dampness will have, making it impossible to be added to the blend to get it to the right level. Contingent upon the wood, a coupling operators may must be included. Corn starch, vegetable oil and other natural material are regularly utilized.Once the pellet is done and cooled it is packed away or put in other impermeable compartments to seal out dampness. Dry pellets smolder productively and clean in both home warming units and business boilers. Since pellets originate from trees, they are renewable and are thought to be carbon nonpartisan. As the world looks for clean different options for fossil powers, similar to coal and petroleum, wood pellets are rapidly expanding in demand and will probably keep on doing as such.

- ▌Sawdust Briquette Making Machine

- ▌Rice Husk Briquette & Pellet Machine

- ▌Horse Manure Briquette Maker

- ▌Mineral Powder / Ore Dust / Iron Ore Briquetting Press

- ▌Coal / Charcoal Briquette Machine